TWIN_STAR:

INNOVATIVE REGISTER CONTROLS FOR PRINTING AND

CONVERTING APPLICATIONS, ALL IN ONE PLACE

The BST eltromat Twin_star register control was specially developed to regulate printed work or a tool station. Optional in-setter control is available to steer a pre-printed web and for the electronic adjustment level of tools.

Twin_star plays a central role in the automation of the operations in this printing process. Use of this BST eltromat register control sustainably reduces set-up times and waste, while it increases the printing machine’s productivity.

BST eltromat- stands for exquisite detection of all print marks

The 1-pixel color camera from BST eltromat also allows the detection of marks with a very low contrast. This means that cold seal and lacquer can be controlled in the web-web comparison. The detected marks are displayed on the operator monitor as a live color image.

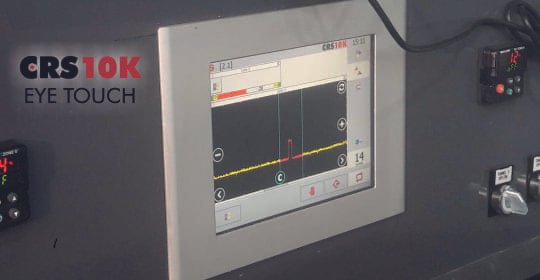

The modern user interface with touch monitor offers individual and efficient handling of the register control system. The clearly designed HMI provides a high degree of operating comfort for the printer.

Tailor-made system for all In-line and Offline applications

The sincon_star is designed for a wide variety of applications where a single register control system for the control of a length and side control channel is needed. Typical applications are:

- Inserting in-register pre-printed material into the process

- Front to backside register control for CI Flexo printing press

- Register control for a downstream unit in line with a CI Flexo printing press

- Register control for a tool station in line with a printing press

Functions:

- Intelligent register mark sensor: 1-pixel colour camera

- Live image of the register marks

- Simple, intuitive operation