WINTRISS- WEB RANGER:

100% SURFACE INSPECTION, PRECISE DEFECT CLASSIFICATION!

Competition in the web processing industry is stiff, and the demands are constantly on the rise. Exact control of the qualities of the outer surface is a prerequisite for defect-free printing products – and for satisfied customers. Here, BST eltromat offers effective support with intelligent systems for 100% quality control during production.

Surface inspection systems provide information on the substrate’s outer surface quality, so that consistently high quality is guaranteed in the subsequent production steps.

BST eltromat Surface Inspection: Your Benefits

- Uninterrupted quality control

- Reliable defect detection

- Fast defect correction

- Increased productivity through automatic monitoring

- Targeted defect prevention based on the analysis of production records

- Reduction in waste and fewer returns

- Increased customer satisfaction

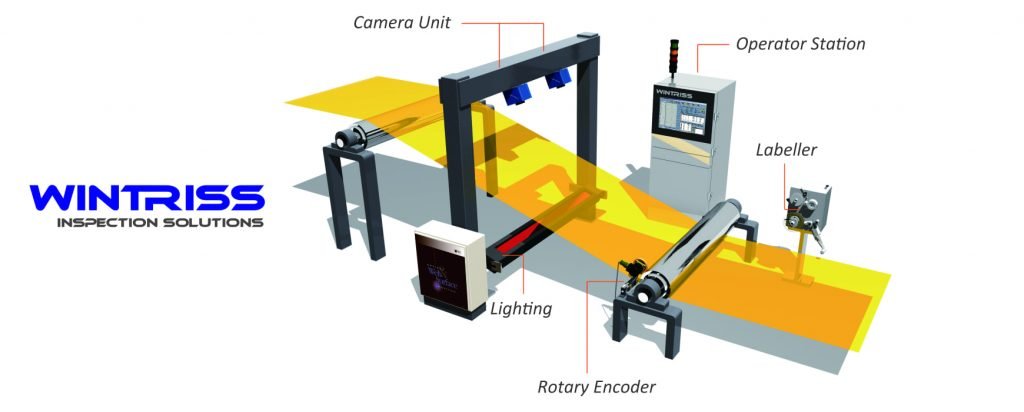

Wintriss Inspection Solutions, Ltd., a subsidiary of California-based Wintriss Engineering Corporation, develops and manufactures optical surface inspection systems using smart, CCD line-scan cameras. Rapidly expanding and with a world-wide presence, Wintriss has installed over 250 inspection systems in North America, Asia, and Europe. Wintriss Engineering is a pioneer in embedding processing intelligence in cameras. After introducing 1st Smart Camera in 1994, we have created increasingly capable cameras with greater processing speed, higher resolution, and standout flexibility, specifically adapted for web and other types of surface inspection applications.

Wintriss Inspection Solutions’ flagship product is the Web Ranger System, which employs the linear cameras in a network-based, distributed architecture. Our core competency is the in-depth understanding of optics and image processing. This expertise and our surface inspection experience enable the company to conceive and implement innovative designs to meet diverse customer requirements for surface inspection. Key patents in image processing and illumination technology are the basis for the exceptional defect detection capability of the Web Ranger System and Wintriss’ market leadership in the inspection of display films.

Optimum Production, Maximum Efficiency

For perfect print results, BST eltromat provides a complete portfolio for quality assurance and maximum productivity in narrow web applications.

With sales and technical support located in India and major international cities, Our Web Ranger system has been installed at over 250 locations in 16 countries worldwide. Wintriss responds instantly to meet customer requirements. We invite you to contact our professional staff for consultation on a solution tailored to satisfy your requirements.

Market leaders in Film, PCB and Nonwovens

Market acceptance in Paper, Glass and Metals

Customer base includes multi-national corporations such as DuPont, Dow-Kokum, Procter & Gamble, GE, Bemis, 3M, U-Japan Nonwoven Co., Havix, Kaneka, Yupo, Nan Ya, AUO, CCP, Chi Mei, H&V, SKC, Shin Kong, PPG, Tredager, TUC, EMC, Lucky Films, Doosan, Dow-Kokum

Installations (USA, Taiwan, China, Korea, Malaysia, Germany, UK, Thailand, India, Indonesia)

Aggressively priced

Local support

Extensive Machine Vision experience

- Smart cameras – 19 years

- Web Inspection – 14 years

Applications: The Web Ranger’s advanced surface inspection classification engine can perform precise defect classification based on extremely subtle differences between defect categories. Using over one hundred extracted features and multiple techniques, the classification engine can be easily trained to reliably recognize distinct defect categories present in the material being inspected. Web Ranger’s superior classification performance greatly enhances product grading, process control and overall quality control. The scope for Wintriss “Web Ranger System” has broader application and it is suitable for wide range of materials:

| No. | Type of Materials | Type of Defects detected by Surface Inspection System |

| 1 | BOPP, BOPET, BOPE, CPP, PVC BOPE, Blown Film, Cast Film, PI, PVB, APET, ABS, PC Boards, PC Film, Diaper Film, Metallized Films |

Fish-eye, Dimple, Void, Scratches, Scratch, Light Crease, Light Area, Heavy Crease, Gel, Dimples, Contamination, Coating Skip, Clear Small Particle, Clear Dimples, Bumps, Adhesive Contamination |

| 2 | Optical BOPET, Polarizer(3, 7 layer), Prism Film, TAC, OPF, Window Film, Micro-lens Film, Coated TAC, Coated PET, PVA, 3D Film, PMMA Boards, Dry Film | Fish-eye, Dimple, Void, Scratches, Scratch, Light Crease, Light Area, Heavy Crease, Gel, Dimples, Contamination, Coating Skip, Clear Small Particle, Clear Dimples, Bumps, Adhesive Contamination |

| 3 | Fibreglass, PrePreg (PP), Cu Foil, Copper Clad Laminate (CCL) | Fish-eye, Dimple, Void, Scratches, Scratch, Light Crease, Light Area, Heavy Crease, Gel, Dimples, Contamination, Coating Skip, Clear Small Particle, Clear Dimples, Bumps, Adhesive Contamination |

| 4 | Air Laid, Spun Bond, Dry laid, Wet Laid, Melt Blown, Spun Laced, Thermal Bonded, Needle Punched, Carded, Glass Mat, Coated Nonwoven, Laminated Nonwoven | Twist-back light, Large Vein Oblique, Hydro-former Streak, Heavy Rope Oblique light, Clump, Binder Void |

| 5 | Aluminium Pin Hole, Aluminium Surface, Stainless Steel | Roller mark, Hole, Deposit, Copper Clear, Bump, Pit, Grease |

| 6 | Float Glass, Patterned Glass for Solar, Piece-by-Piece Glass, Display Glass | Stones, Knots, Bubbles |

| 7 | Tire Cord, Technical Textile | Water Marks, Streaks, Smudge, Pin Hole |

| 8 | Coil Coating | Holes, Doughnuts, Paint Drip, Fisheyes, Dirt Line Specs, Ghosting |

| 9 | Base Paper and Paper Boards, Coated Paper and Paper Boards(Art Paper), Industrial Paper(Liner), Cigarette Paper, Tissue Paper |

Water Marks, Streaks, Smudge, Pin Hole, Insect, Creases, Chunks |

| 10 | Cu Electrode, Al Electrode, Battery Separator Film, Solar Back Sheet, Aluminium Foil Package | Streaks, Creases, Scratches, Bumps |

Battery Film

Coated Paper

Copper Foil

FibreGlass

OPF Films

Paper

PCB dry film

Pet

Polarizer Film

Pre_preg

Window Film

Non Woven

Defects detected

Clump

Coating Skip

Creases

Dimples

Dirt Lines

Fish eye

Gel

Holes

Insects

Knots

Light Area

Light Crease

Particles

Scratches

Smart Camera Stand-alone Web Inspection System

8192 Pixel CMOS sensor

7um x 7um pixels

Vaiable scan rate

Up to 80,000 lines per sec

7448 Pixel CCD

4.7 x 4.7 miron pixel size.

Veriable Scan rate

Up to 10,320 lines/sec at 7448 pixels

Up to 390,000 lines/sec at 256 pixels

Lighting

Compact, Energy-Efficient Lightsource for surface inspection application

Win7x64

Inspetion Software

Web Ranger 2000

Database

Mirosoft SQL Server

Labeller

Up to 300 M/min

Automatic calibration

Preurized roller for robust tagging

Tagger roll omplete alarm

Tag dispensing speed controlled

Up to 3000 M/min

Automatic edge traking

PLC control

Automatic/manual mode selection